Attention!

Inspect all materials carefully before installation. Warranties do not cover materials with visible defects once they are installed. The natural characteristics of wood cause variations in color, grain etc. Even though our products are inspected many times, some grading deficiencies may occur; allow for up to 15% of the boards.

Rhodium Floors prohibits the use of any adhesive tape on the flooring at any time during installation or thereafter. This includes painter’s tape whether green or blue or masking tapes. Such use of tape will void the Warranty and no claims will be addressed in regards to defects in the finish as a result of the use of tape. The industry rule is to tape only paper-to-paper or paper-to-trim.

We DO NOT recommend that you use red rosin paper as the pigment can bleed through and stain your floor. We are therefore advising that this paper be replaced non-pigmented brown paper.

Owner/Installer Responsibility

The installer assumes all responsibility for the final inspection of product quality. This inspection of all flooring should be done prior to installation. Carefully examine flooring for quality, finish and color before installing it.

The installer must use reasonable selectivity and hold out or cut off pieces with deficiencies, whatever the cause. If material is doubtful as to grade, manufacture or factory finish, do not install it and contact your retailer immediately.

The installer/owner is responsible for determining if the job site sub-floor and job site conditions are structurally and environmentally acceptable for installation. The manufacturer declines any responsibility for floor failure resulting from or connected with sub-floor, subsurface, job site damage, jobsite environmental deficiencies or deficiencies after hardwood flooring has been installed.

All substrates must be dry, clean, structurally sound, and level. When flooring is ordered, at least 5% must be added to the actual square footage needed to allow for cutting and grading deficiencies.

Use of appropriate products for correcting sub-floor voids should be accepted as a normal industry practice.

All installations

Breathing protection, broom or vacuum, chalk line & chalk, electric power saw, eye protection, hammer, hand saw or jamb saw, moisture meter (wood, concrete or both), hardwood floor cleaner, square, tape measure, utility knife, wood or plastic wedges (1/2” spacers).

Add for staple or nail-down

1 1/2” staples or cleats (minimum), power nail model #45 or compressor, in-line regulator, nylon/plastic tapping block, Stanley-Bostich 3297 or Senco SLS 20.

Caution: Be careful when using a power nailer, as improper use can mark the surface of the flooring.

Add for floating installation

Carpenter’s Wood Glue, moisture barrier (6 or 8 mil polyethylene foil), resilient sub-floor covering (optional).

Job Site Inspection

Exterior grading should be complete with surface drainage offering a minimum drop of 3” in 10’ to direct flow of water away from the structure. All gutters and downspouts should be in place.

All outside doors and windows must be in place. All concrete, masonry, plastering and other “wet” work must be thoroughly dry. The wall coverings should be in place and the painting completed except for the final coat on the base molding. When possible, delay installation of base molding until flooring installation is complete. Basements and crawl spaces must be dry and well ventilated.

Flooring may be installed below, on, or above grade level.

Crawl spaces must be a minimum of 24” from the ground to underside of joists. A ground cover of 8 mil polyethylene film is essential as a vapor barrier with joints lapped 8 inches. The crawl space should have perimeter venting equal to a minimum of 1.5% of the crawl space square footage. These vents should be properly located to foster cross ventilation (see figure 1). Local regulations may prevail.

Do not install flooring in full bathrooms. The installation site should have a consistent room temperature of 60-80° F and humidity of 35%-65% for 14 days prior to, during and after installation, to allow for proper acclimation.

The sub-floor must be checked for moisture content by an appropriate testing method. Test results must be recorded.

Storage and Handling

Handle and unload with care. Store in a dry place; make sure to provide at least a four-inch air space under bundles and to store bundles upon “on-grade” concrete floors. Flooring should not be delivered until the building has been closed in with windows and doors in place and until cement work, plastering and all other “wet” work is completed and dry. Concrete should be at least 60 days old. Flooring must be stored in the environment in which it is expected to perform for at least 72 hours prior to installation.

Sub-floor Preparation and Recommendations for all Installations

Concrete sub-floors

New concrete slabs require a minimum of 60 days drying time before covering them with a wood floor. (The slabs must be fully cured.) Concrete sub-floors must be dry, smooth (level within 1/4” in a 10-foot radius, 1/8” in 6’) and free of structural defects. Hand scrape or sand with a 20-grit #3-1/2 open face paper to remove loose, flaky concrete. Grinding high spots in concrete is recommended over using filling compounds. However if a filling/leveling compound is used, it must be of a Portland-base compound (min. 3,000 p.s.i.) with a high compressive strength.

Concrete must be free of paint, oil, existing adhesives, wax, grease, dirt, sealers, and curing compounds. These may be removed chemically or mechanically, but do not use solvent based strippers under any circumstances, because residual solvents can prohibit the satisfactory bonding of flooring adhesives. It is important to ensure a long lasting bond between the adhesive, the concrete, and the planks. Flooring may be installed on grade, above grade, as well as below grade where moisture conditions do not exist.

To ensure a long lasting bond, make sure that the perimeter of the foundation has adequate drainage and vapor barrier.

Lightweight concrete

Lightweight concrete that has a dry density of 100 pounds or less per cubic foot is not suitable for wood flooring. Many products have been developed as self-leveling toppings or floor underlayments, so it is important always to follow glue manufacturer instruction in regards to procedures for underlayment and self-leveling toppings. Materials for these purposes include cellular concrete, resin reinforced cement, and gypsum-based materials.

Although some of these products may have the necessary qualifications of underlayment for wood flooring installations, others do not. To test for lightweight concrete, scrape a coin or key across the surface of the sub-floor. If the surface powders easily or has a dry density of l00 pounds or less per cubic foot, do not install wood flooring.

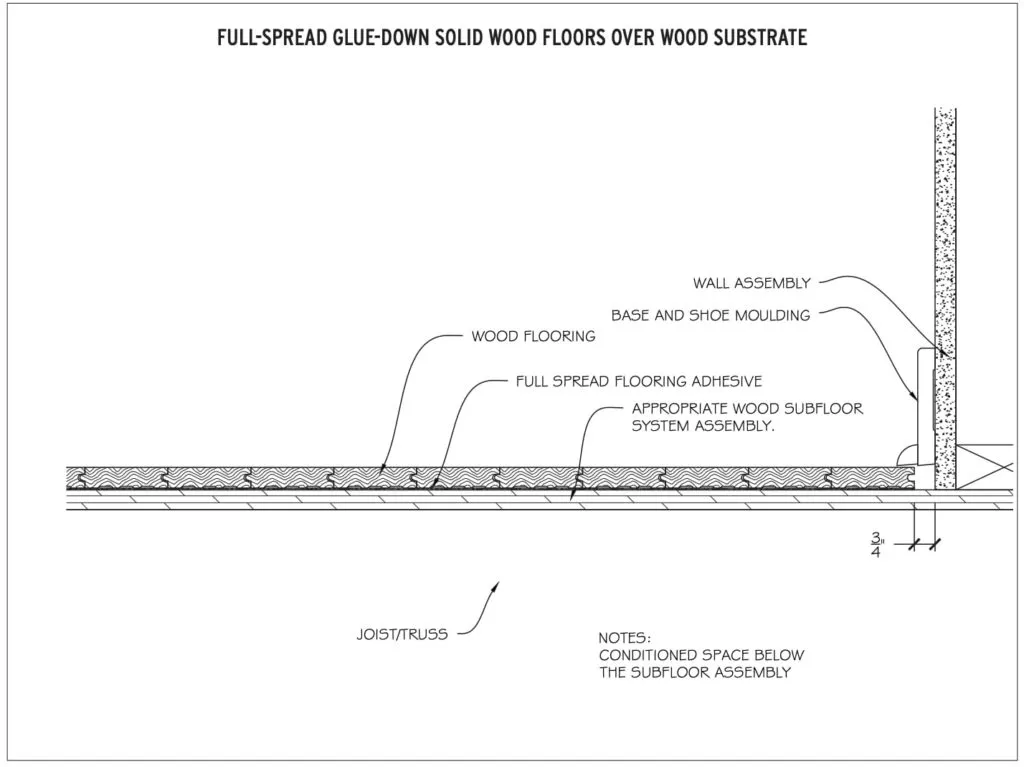

Wood sub-floors

Wood sub-floors need to be well nailed or secured with screws. Nails should be ring shanks, and screws must be counter sunk. The wood sub-floor needs to be structurally sound (meaning without loose boards, vinyl, tiles, or OSB board or plywood) and dry. If the sub-floor is single layer, less than 3/4” thick, add a single cross layer for strength and stability (minimum 5/16” thick for a total 1” thickness).

This is to reduce the possibility of squeaking. Wood sub-floors must be free of paint, oil, existing adhesives, wax, grease, dirt and urethane, varnish etc. Underlayment grade OSB (not the wax side) is also a suitable sub-floor. Particleboard is not an acceptable subfloor for staple or nail down installation, but can be used as a sub-floor in glue down installations. When installing over existing wood flooring, install at right angles to the existing floor.

Sub-floor moisture check

The recommended wood flooring adhesive may be used for above, on, and below grade applications and on all common substrates. On and below grade applications are susceptible to moisture and should be tested for moisture content prior to installation in several locations within the installation area. Acceptable conditions for above, on, and below grade applications are:

- Less than 3lbs/1000 sq. ft./24 hrs. on a calcium chloride test.

- No greater than a reading of 4.5 on a Tramex Concrete Moisture Encounter (moisture meter).

- Wood Substrates must have a moisture reading of less than 12% when using a Tramex, Delmhorst or equivalent moisture meter and be within 3-4% moisture content of the flooring installed. To correct any sub-floor problems concerning moisture, either wait until the sub-floor dries to meet specifications or use an appropriate moisture barrier. All sub-floor moisture readings must be recorded.

Sub-floors other than wood or concrete

Perimeter glued resilient vinyl and rubber tiles are unacceptable underlayments and must be removed. Terrazzo, tile and any other hard surfaces that are dry, structurally sound and level, as described above, are suitable as a subfloor for installation. As above, the surface must be sound, tight and free of paint, oil, existing adhesives, wax, grease and dirt. Terrazzo and ceramic tile must be scuffed to assure adhesion.

WARNING! Do not sand existing resilient tile, sheet flooring, backing, or felt linings. These products may contain asbestos fibers that are not readily identifiable. Inhalation of asbestos dust can cause Asbestosis or other serious bodily harm. Check with local, state and federal laws for handling hazardous material before attempting the removal of these floors.

Radiant heated sub-floors

We recommend that only oak, kambala, walnut, afzelia doussié, afrormosia, and merbau species be used for radiant heat installations. At the present time the other species should NOT be used for this purpose.

Radiant-heated floors require more time for installation – be patient or do not do them! Because the radiant heat dries out wood, it is very important to acclimate flooring material in the following manner.

Rack out the boards so that they are joined together, the tongues fitted in the grooves, but not affixed with glue. Turn on the radiant heat to a comfortable level, as if the space is lived in. The flooring should remain in this racked out condition as long as it takes to bring the material to moisture equilibrium with the environment – minimum 10-12 days. Do not use high or low temperature extremes during the racking-out process. The key to a successful installation is having the radiant heat turned on to a comfortable level at which the space will be lived in.

Important! When radiant heat is installed in concrete, mortar beds, or gypsum cement, you must wait until these bases are completely dry before installing flooring on top. (This can take several weeks. Again, be patient!) Wait until the humidity in the structure stabilizes to the average level expected for the area in which the flooring will be installed. Then allow the flooring to acclimate to this humidity level before installation. This will minimize dimensional changes due to moisture.

Caution: The subfloor surface must never exceed 80° Fahrenheit in temperature.

Preparation

Remove all moldings and wall-base, and undercut all door casings with a hand or power jam saw using a scrap piece of flooring as a guide.

“Racking the Floor”:

Whether you choose to install the floor by the glue down method, nail or staple down or floating, start by cutting four to five

planks in random lengths, differing by at least 18”. As you continue working across the floor, be sure to maintain the 18” minimum between end joints on all adjacent rows. For floating installation increase the end gaps to 24” (See Figures 2 & 3).

Never waste material; use the left over pieces from the fill cuts to start the next row or to complete a row. Note: When installing, be sure to blend the wood from several cartons to ensure a good grain and shading mixture throughout the installation. Allow for a 1/2” expansion gap all around the room.

Recommended Sub-floor Surfaces

Glue-down:

3/4” chip, wafer board and particleboard Acoustic concrete Acoustic cork underlayment Ceramic, terrazzo, slate and marble Concrete slabs Existing solid wood flooring Metal Preferred: 3/4” (19 mm) CDX grade plywood or 3/4” OSB, stamped, PS2 rated underlayment, Minimum: 5/8” CDX grade plywood Vinyl, resilient tile, cork flooring.

Staple or nail-down:

3/4”chip, wafer board Existing solid wood flooring Preferred: 3/4”(19 mm) CDX grade plywood or 3/4” OSB PS2 rated underlayment, Minimum: 5/8” CDX grade plywood Vinyl, resilient tile, cork flooring

Floating:

Concrete slabs

Existing solid wood flooring

Glue Down Installation Guidelines

Radiant heat sub-floors:

A. We recommend that only oak, kambala, walnut, afzelia doussié, afrormosia, and merbau species be used for radiant heat

installations.

B. Radiant heat conditions require glue-down installation only.

C. The maximum temperature of sub-floor under normal use should not exceed 80°F. (Check with heat system manufacturer).

D. For correct water temperature inside heating pipes, check with manufacturer’s suggested guidelines.

E. Heating pipes must be covered with 1-1/4” of concrete or minimum 1/8” below bottom side of plywood sub-floor. In addition, for plywood sub-floor, heat transfer plates or insulation boards must be under pipes.

F. Before installation of flooring, heat system must be operated at normal living temperature for a minimum of 14 days at the time of installation. The sub-floor should be 64 -68 °F).

G. Room temperature should not vary more than 15 °F season to season – 35% to 65% humidity in home for radiant heated rooms.

H. Must be an approved radiant heat system (8 watts per square foot heating capacity).

I. If you have questions, please contact Rhodium Floors for Manufacturer specific instructions!

Below grade:

A concrete slab is considered below grade when any part of the slab is below ground level, for example, walk-out basements are below grade. Treat with Bostik’s MVP first. For floating installations use 6 mil visquine underneath tight cell foam underlayer unless visquine is already applied to foam underlayer.

Step 1 – Getting started

Select a starter wall. It is recommended to start the installation along an exterior wall, because it’s more likely to be straight and square with the room. Measure out from the wall the width of two planks plus a 1/2” expansion gap and mark each end of the room and snap your chalk line. Secure a straight edge on the chalk line before you spread your adhesive to ensure alignment, a critical part of the installation. This prevents movement of the planks that can cause misalignment.

Step 2 – Spreading the adhesive

Use the trowel recommended by the adhesive manufacturer at a 45° angle (See Figure 4) to get the proper spread of adhesive

applied to the sub-floor is important in order to produce a proper and permanent bond. Improper bonding can cause loose or hollow spots. Spread adhesive from the straight edge out about 2 1/2’ (30 in.). Working in small sections is helpful for this method as it will allow you to reach across the adhesive to install the wood flooring without putting any weight on it and will ensure proper transfer of the adhesive to the wood flooring.

Note: Change the trowel every 2000 to 3000 square feet due to wear down of the notches. This assures you always get the

proper spread of adhesive.

Step 3 – Install your starter rows

Install the first row of starter planks with the tongue side of the plank facing the straight edge and secure into position. Pull in tight together at seams and continue with installation.

Step 4 – Job completion

Once the starter rows are secure, spread 2-1/2 feet of adhesive along the length of the room (See Figure 5). Never spread more adhesive than can be covered using the open time recommendation listed in the instructions on the adhesive label.

Never lay planks further than you can comfortably reach. Place tongue into groove of planks and press firmly into adhesive. Never slide planks through adhesive.

Test for proper bond by occasionally lifting a board and looking for good coverage (90%), then replace it into the adhesive. Clean any adhesive off the surface before it cures. Hold planks securely in place as you are installing and continue the process throughout the installation. Use caution when using a rubber mallet to butt material together, as it can burnish the finish and cause marring. Note: Never work on top of the flooring when installing with the glue down method.

Staple or Nail Down Installation Guidelines

Flooring may be installed over wood sub-floors using staples or nailing cleats. When installing flooring by nailing or stapling, it is necessary to use the proper type of flooring stapler or nailer.

Step 1 – Getting Started

You must staple or nail 1” – 2” from the ends and every 4”– 6” along the edges. This will help insure a satisfactory installation. It is best to set the compressor PSI at 80 – 85lbs. to keep the staples from going through or breaking the tongues. Improper stapling techniques can cause squeaks in the floor. Adjustments may be necessary to provide adequate penetration of the nail or staple into the nail bed. You want it flush in the nail pocket. Use a scrap piece of flooring material to set tools properly before installation. Before installation of the engineered flooring begins, install a 15 lb asphaltic felt or its equal over the sub-floor. This will retard moisture from below and may help prevent squeaks. Keep in mind there is no complete moisture barrier system for staple or nail down installations.

Step 2 – Laying out the job

Measure out from the ends of your starting wall, 8” when installing 71/2” wide planks or 10” when installing 9 ½ wide wood planks, and mark both ends. Where possible, lay the flooring at 90° angles to the floor joists. Make a chalk line along the starting wall using the marks you made.

Step 3 – Beginning installation

Place the planks with the tongue facing away from the wall and along your chalk line. Use brads or small finishing nails to secure the first starter row along the wall edge 1” – 2” from the ends and every 4” – 6” along the side. Counter sink the nails and fill with filler that blends with the flooring installed. Place the nails in a dark grain spot in the board. The base or shoe molding will cover the nails when installed, after completion of the installation. Blind nail at a 45° angle through the tongue (See Figure 7). It will be easier if you pre-drill the holes in the tongue.

Nail 1” – 2” from the ends and every 4” – 6” along the sides. It will be necessary to blind nail the next 2 rows. A Stanley BT35

brad nailer with 1” – 13/8” brads can also be used to blind nail and no predrilling is needed. Continue the installation using the recommended engineered wood flooring stapler or nailer, using staples or nailer cleats recommended. Nail or staple the flooring 1” – 2” from the end and every 4” – 6” along the edge tongue.

Step 4 – Final touches

Install the proper trim molding at the doorways to achieve the transition and along the walls to cover the edges of any gaps along the wall due to irregularity. Complete the job by using filler that blends with the installed flooring to fill any gapping along the joints and clean the finished floor with the recommended hardwood floor cleaner.

Floating Installation Guidelines

Step 1 – Sub-floor preparation:

As part of your sub-floor preparation, remove any existing base, shoe mold, or doorway thresholds. These items can be replaced after installation, but should be replaced in such a way to allow at least 1/2” “room for expansion” around the perimeter of the room. All door casings should be notched out or undercut to allow 1/2 inch room for expansion and to avoid difficult scribe cuts. This is easily done by placing a piece of flooring on the sub-floor as a height guide for your hand saw.

Note: In large areas measuring more than 24 lineal feet, use 1/4” expansion for each 12 linear feet width and length (i.e., 48’ x 48’ leaves 1” expansion on all sides).

Step 2 – Installing the floor:

Once the 6-8 mil poly and the resilient sub-floor covering (if used) have been installed over the sub-floor, the jobsite is ready for the WWL boards. Never open the bundles until ready to start the installation process. When the decision is made on the direction the boards will run, start at one side wall with the first row of boards allowing a 1/2” expansion along side and end walls (Fig. 8) with the use of wood wedges (equivalent spacers). If the starting wall is out of square, it is recommended the first row of boards be Figure 10 scribed to allow for 1/2” of expansion (Fig. 9) and a straight working line.

Side and End gluing:

The flooring boards must be side and end glued using Carpenter’s Wood Glue. Apply in 8” long sections with 12” between each 8” section. Each 8” glue line is flush to the top of the groove. (See Fig. 10).

Fully glue every end joint. If any excess glue squeezes up to the finished surface, wipe off using a paper towel or cloth. Install the first row using the appropriate expansion space with the groove side facing the wall.

The subsequent rows are installed, side and end glued, tap together with a hammer and tapping block to prevent damage to the protruding tongue (Fig. 11).

Tapping block should be against tongue only. Use only flat side of tapping block against tongue. Do not tap on groove side of flooring as this will cause damage! Check for tight fit on sides and ends. Stagger 18 inches between end joints of adjacent board rows (see Fig. 2 & 3). End joints should not repeat visually across installed floor. Never install without some end joints in the floor.

Installing the last row:

Most often the last row does not fit in width. When this occurs, follow this simple procedure: lay a row of boards, unglued, tongue toward wall, directly on top of last installed row (Fig. 12).

Take a short piece of flooring with the face down and the tongue side against the wall. Draw a line with a pencil along the row moving down the wall. The resulting line gives the proper width for the last row which, when cut, can then be wedged into place using a crow bar or TarkTool. Make sure when the installation is complete that wedges and spacers are removed and the expansion space is covered with an appropriate molding. Always attach the trim to the wall or vertical object and never to the flooring boards. Note: For additional information on installation over radiant heated floors please contact Supplier or Manufacturer.

.svg)